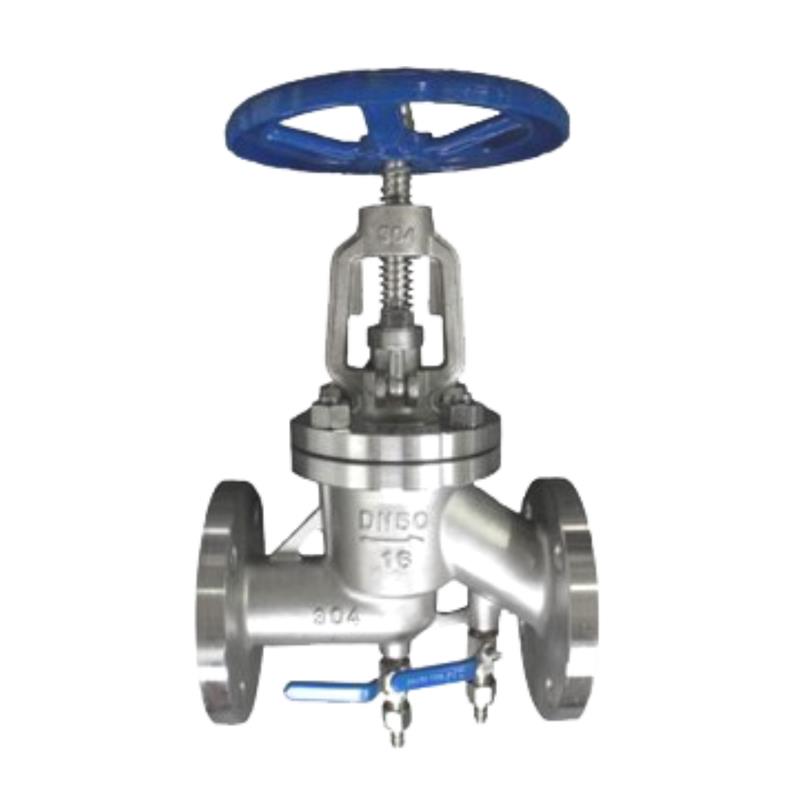

The Antibiotic Shut-Off Valve features a globe valve design with a precision-controlled stem and seat, which allows for full shut-off or flow regulation of antibiotics and other pharmaceutical fluids. The unique feature of the valve is its bellows seal or sanitary sealing mechanism, which prevents any leakage around the stem and ensures that no contamination occurs during operation.

When the valve stem is turned (manually or via actuator), the valve plug either opens or closes, allowing precise control over the flow of the fluid. The bellows seal (or equivalent technology) keeps the valve stem completely sealed, preventing leakage, even when the valve is subjected to high pressure or demanding conditions.

Why Choose Our Antibiotic Shut-Off Valve?

- Zero Leakage: Provides complete zero-leakageoperation, ensuring no contamination during sensitive pharmaceutical processes.

- Hygienic Design: Manufactured to meet the strict hygienic standardsrequired for pharmaceutical and biotech applications.

- Durable & Corrosion-Resistant: Made from high-grade stainless steeland corrosion-resistant alloys, ensuring long-lasting reliability in harsh conditions.

- Precise Control: Provides accurate flow regulation, ideal for controlling antibiotic or medication flows in critical systems.

- Maintenance-Free: The valve is designed for maintenance-free operation, reducing costs and ensuring continuous, reliable operation.

- Versatile Applications: Suitable for a wide range of pharmaceutical, biotech, and medical fluid systems.