|

Parameter

|

Details

|

|

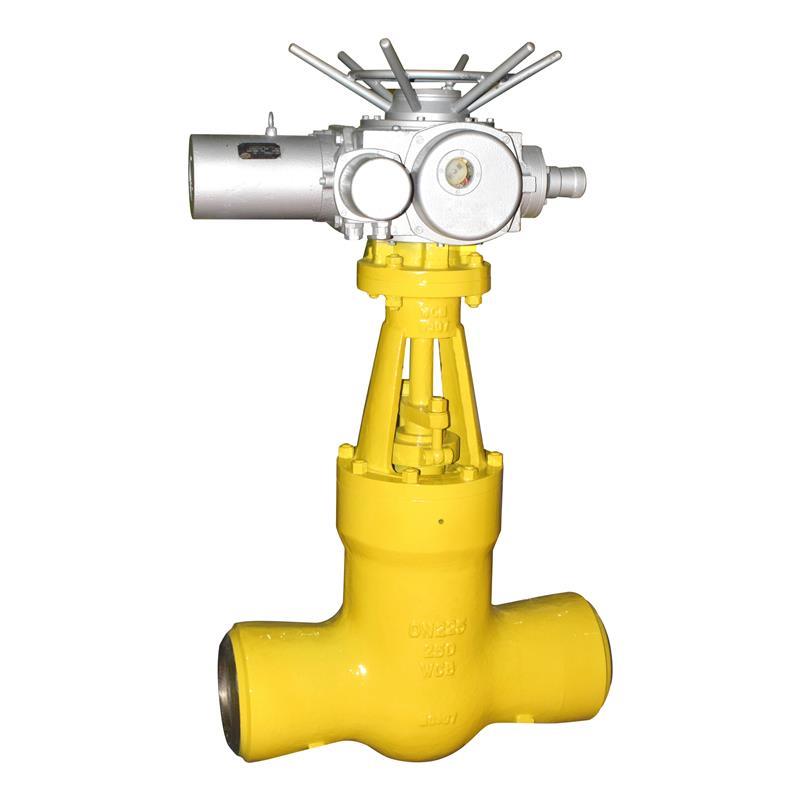

Size Range

|

2" to 48" (DN50 to DN1200)

|

|

Pressure Rating

|

Class 150 to Class 2500 (PN16 to PN420)

|

|

Temperature Range

|

-29°C to 425°C (-20°F to 800°F)

|

|

Body Material

|

ASTM A216 WCB, WCC, LCB, LCC, WC6, WC9, C5, C12, etc.

|

|

Trim Material

|

13% Cr, SS304, SS316, Stellite, Monel, Inconel, etc.

|

|

Seat Type

|

Metal-to-metal or resilient seated

|

|

Stem Material

|

SS410, SS304, SS316, Alloy 20, etc.

|

|

Actuator Type

|

Electric motor-operated (on/off or modulating)

|

|

Voltage

|

24V DC, 110V AC, 220V AC, 380V AC, etc.

|

|

End Connections

|

Flanged (ASME B16.5, B16.47), threaded (NPT, BSP), or butt-weld (B16.25)

|

|

Leakage Class

|

API 598 (Class IV, V, or VI)

|

|

Standards Compliance

|

API 600, ASME B16.34, ANSI B16.10

|

|

Testing

|

Hydrostatic, shell, and seat testing per API 598

|